Keratin Materials

Cosmetics, Hair care & growth,

Leather industry, Animal feed,

Tissue engineering, Controlled released & delivery,

Vascular graft Wound healing, Hemostasis, Bone regeneration, Peripheral nerve

repair,...

Keratin ([1][2])

is one of a family of fibrous structural proteins. It is the key

structural material making up hair, horns, claws, hooves, and the outer layer of human skin. Keratin is also the protein that protects epithelial cells

from damage or stress. Keratin is extremely insoluble in water and organic

solvents. Keratin monomers assemble

into bundles to form intermediate filaments, which are tough

and form strong unmineralized epidermal

appendages found in reptiles, birds, amphibians, and mammals.[3][4] The

only other biological matter

known to approximate the toughness of

keratinized tissue is chitin.[5][6][7].

https://en.wikipedia.org/wiki/Keratin

Examples of occurrence

Keratin filaments are abundant in keratinocytes in the cornified layer of the epidermis; these are proteins which have undergone

keratinization. In addition, keratin filaments are present in epithelial cells

in general. For example, mouse thymic epithelial cells (TECs) are known to react

with antibodies for keratin 5, keratin 8, and keratin 14. These antibodies are

used as fluorescent markers to distinguish subsets of TECs in genetic studies of

the thymus.

- the α-keratins are found in all

vertebrates. They form the hair (including wool), stratum corneum, horns, nails, claws and hooves of mammals and the hagfish slime

threads.[4]

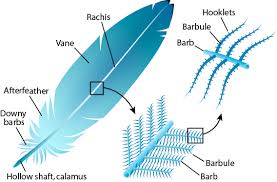

- the harder β-keratins are found only in the sauropsids, that is all living reptiles and birds.

They are found in the nails, scales, and claws of reptiles, some reptile shells (Testudines, such as tortoise, turtle, terrapin), and in the feathers, beaks, and claws of birds.[11] (These

keratins are formed primarily in beta sheets. However, beta sheets are also found in

α-keratins.)[12]

Additionally, the baleen plates of filter-feeding whales are made of keratin.

|

Horns such

as those of the impalaare

made up of keratin covering a core of live bone. |

|

Keratins (also described as cytokeratins) are polymers of type I and type II intermediate filaments, which have only

been found in the genomes of chordates (vertebrates, Amphioxus, urochordates).

Nematodes and many other non-chordate animals seem to only have type VI intermediate filaments, lamins, which have a long rod domain (vs. a short rod

domain for the keratins). |

|

|

|

Keratins are naturally derived proteins that can be fabricated into several

biomaterials morphologies including films, sponges and

hydrogels. As a

physical matrix, keratin biomaterials have several advantages of both natural

and synthetic materials that are useful in tissue engineering and controlled

released applications. Like other naturally derived protein biomaterials, such

as collagen, keratin possess amino acid sequences, similar to the ones found on

extracellular

matrix (ECM), that may interact with

integrins showing their

ability to support cellular attachment, proliferation and migration. The ability

of developing biomaterials that mimic ECM has the potential to control several

biological processes and this is the case for keratin which has been used in a

variety of biomedical applications due to its biocompatibility and

biodegradability.

https://pdfs.semanticscholar.org/ab50/ecefd0eb689b0cbd09ddb0589aa865ad1c64.pdf

Keratin Application Market Analysis

Extraction of keratin from keratinaceous substrates

Keratins are removed from the cortex first by using chemicals to break the

disulfide bonds that are prevalent in keratinized tissues. The alpha and

gamma-keratins are converted to their non-crosslinked forms by oxidation [22,

2426] or reduction [22, 27-29], during which cystine is converted to either

cysteic acid or cysteine, respectively. The free proteins extracted with

denaturating solvents produce a solution that can be purified by filtration and

dialysis.

Keratin-based biomaterials fabrication

The interest of using keratin as a biomaterial in medical applications is based on several key properties that

contribute to the overall physical, chemical and biological behavior of these

biomaterials. Extracted keratin proteins have an intrinsic ability to

self-assemble and polymerize into fibrous and porous films gels and scaffolds.

The spontaneous selfassembly of keratin has been studied extensively at both

microscale [35-37] and macroscale levels [38]. Furthermore, the presence of cell

adhesion sequences, arginine-glycine aspartic acid (RGD) and leucine-aspartic

acid-valine (LDV) on the keratin protein derived from wool and hair, makes

keratin biomaterials able to support cell attachment and growth.

Keratin Films and Coatings

Keratin films can be prepared by solvent casting. This technology is becoming

increasingly attractive for the production of films with extremely high quality

requirements. The advantage of this technology includes uniform thickness

distribution, maximum optical purity, and extremely low haze and is a technique

easy to use. The ability of keratin solution to self-assemble into films was

described by Yamauchi et al. [56] and, the physicochemical properties and

biodegradability of the solvent-cast keratin films were evaluated. Pure keratin

films presented low mechanical strength but the addition of glycerol resulted in

transparent films, with increased mechanical strength, flexible and

biodegradable both in vitro (trypsin) and in vivo (subcutaneous implantation in

mice) [56]. Furthermore, these films proven to promote and increased cell

adhesion and growth when compared to collagen and glass.

Keratin 3D-Constructs

The ability of extracted keratin to self-assemble into three dimensional porous

structures has led to their development as scaffolds for biomedical

applications. The sponge scaffolds were fabricated by lyophilization of an

aqueous keratin solution after controlled freezing. This resulted in sponges

with homogeneous porous microstructures. Lyophilization or freeze-drying

technique is based upon the principle of sublimation. The protein solution, of

desired concentration, is frozen and solvent is removed by lyophilization under

the high vacuum. Porous structures are formed from the voids left by the removal

of the solvent. Thus, the frozen solvent acts as porogen to produce porous

materials. The pore size can be controlled by the freezing rate and pH; a fast

freezing rate produces smaller pores.

Keratin-based drug delivery systems

Drug delivery which takes into consideration the carrier, the route of

administration and the target, has evolved into a strategy of processes and

devices designed to enhance the efficacy of therapeutic agents through

controlled release. For many drug applications controlled drug delivery has even

become a prerequisite to achieve therapeutic efficacy and/or avoid adverse side

effects [87, 88]. Controlled drug delivery systems are not only to protect and

stabilize the incorporated drug but also help to maintain significant local

levels for sustained therapeutic response at low frequency of administration.

Biomaterials for controlled drug delivery systems have to meet several

requirements.

A variety of polymers have been investigated for drug delivery purposes However,

there remains a need for biomaterials that can be highly controlled in terms of

composition and sequence, structure and architecture, mechanical properties and

function. To address these requirements, the exploration of keratin as a

biomaterial for controlled drug delivery has widely expanded over the last few

years. The most common and easiest way of incorporating drugs into keratin

biomaterials is by dissolving or mixing them directly into the keratin solution

before processing. The challenge of this method is to ensure that there is no

detrimental impact of the fabrication process on the integrity and bioactivity

of the drug. Keratin can be used to increase the release in highly hydrophobic

and non-degradable systems. The release rate can be modulated by film

composition and that the mechanism is dominated by film degradation and

diffusion [92]. In this way, keratin can be used to increase the release in

highly hydrophobic and non-degradable systems. The incorporation of drugs into

nanoparticles is another option. It was shown that higher release rates are

obtained at intracellular level (higher GSH concentration) with efficient

internalization showing the promising applications of keratin-g-PEG as drug

carriers for cancer therapy.

Keratin in biomedical applications

Keratin have a strong potential for development as clinically relevant

biomaterials because they are abundant, bioactive and a realistic source of

autologous proteins.

Ocular surface reconstruction:

The results suggested that keratin films could represent the replacement of the

amniotic membrane in ophthalmology because keratin films are more transparent

and stiffer than AM with similar levels of corneal epithelial cells attachment

and proliferation.

Hemostatic agent:

Keratin hydrogels for the treatment of acute myocardial infarction, promoting

angiogenesis. It was hypothesized that keratin hydrogel has the ability to

adsorb fluid and bind cells to act as an effective hemostatic agent.

Nerve tissue regeneration:

The studies revealed that keratin biomaterial is neuroconductive and contain

regulatory molecules capable of enhancing nerve tissue regeneration by enhancing

the activity of Schwann cells.

Wound healing:

Cross-linked keratin powder, films and hydrogels showed significant proliferation of wound healing cell lines like

microvascular endothelial cells, keratinocytes and fibroblasts. Moreover,

incubation of keratin materials with lymphocytes (T cells) and activated

lymphocytes showed, respectively, no proliferation and normal growth, indicating

that keratin materials are nonimmunogenic and that the body’s normal

cell-mediated immune response is not inhibited by keratin materials.

These were also applied to wounds on animals (rats) and humans, and a faster

healing of the wounds treated with keratin materials was observed and, in the

human model, with reduced pain [47, 49]. It was investigated the biological

mechanism underlying the observed clinical benefits of keratin-based products as

wound treatments [109]. The results suggested that the beneficial effects of

keratin are related to its positive effects on re-epithelialization via

stimulation of keratinocyte migration and production of collagen type IV and

VII.

|

|

|

|